VARIOROL

Magnetic doctor blade technology has been used successfully in the printing and coating industry for over 40 years. Based on this, we have further developed the VARIOROLL coating technology.

The solution was infinitely variable application quantity regulation and changing to a different web width during production – without downtime or changing dosing rollers. This system has now been successfully in use for over 10 years.

They are used on web materials (paper, cardboard, corrugated cardboard, films) from laboratory widths to 3.5 m production widths. Guaranteed uniformity of application across the width and length of the web.

The new coating process developed by TIMATEC is the logical further development of magnetic doctor blade technology. The key feature here is that a predetermined quantity of substance is pre-dosed onto the magnetic roller by means of a driven dosing roller, which serves as a transfer element. The direction of rotation, rotational speed (friction), contact distance and transmission pressure must be reproducibly set.

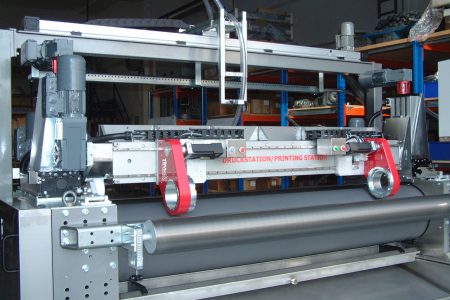

VARIOROL – APPLICATION SYSTEM with INDIRECT TRANSFER

Pre-dosing with 1 dosing roller on the magnetic roller. Transfer to the web by friction (differential speed between web and roller) and contact distance. The order quantity can also be changed during production for different web widths without downtime! V/max: up to 200 m/min, depending on the task.

Maschinen- und Anlagenbau

A-9220 Velden(Austria)

Klagenfurter Straße 45c

Telefon Tel.: 0043 680 333 2818

E-Mail: tischler@timatec.at