TIMATEC COATING GMBH has also been active in the EPS industry for over 20 years with the manufacture of special machines for staplers.

There is also a very successful market in the EPS industry with machines and systems for underfloor heating and its insulation measures for the quick and easy installation of heating pipes on EPS boards using the TACKER system.

A very cost-effective installation system with plastic clips with barbs for various pipe diameters from 6 to 20 mm with pipe lifting function for complete encasing of screed, resulting in ideal heat transfer in the screed.

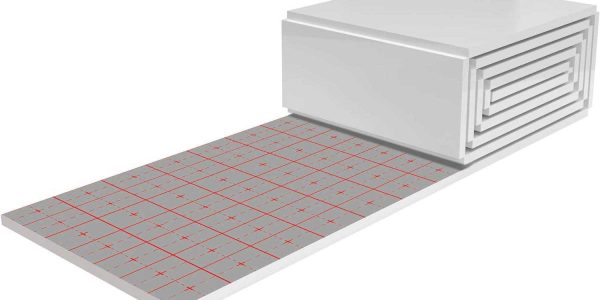

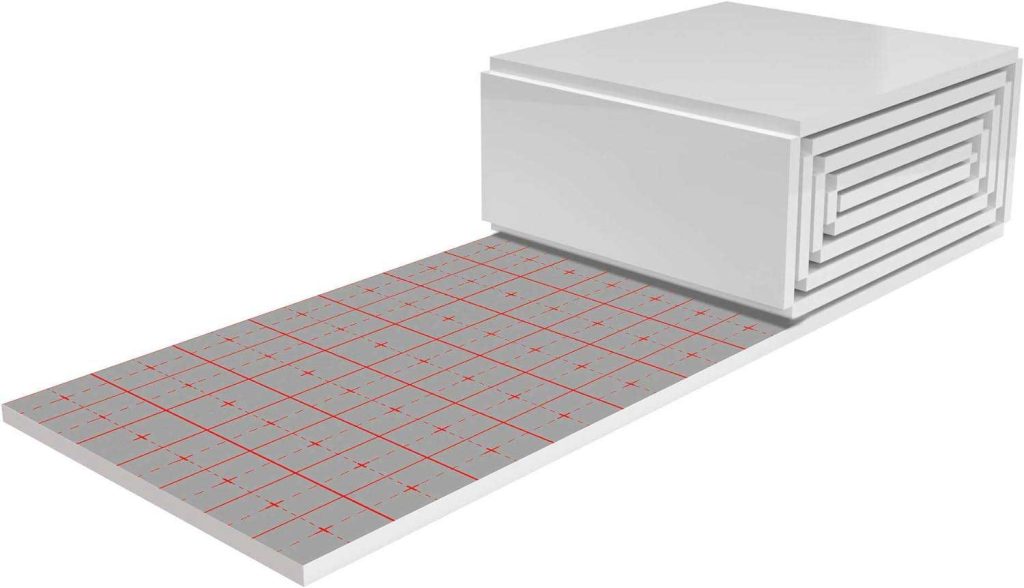

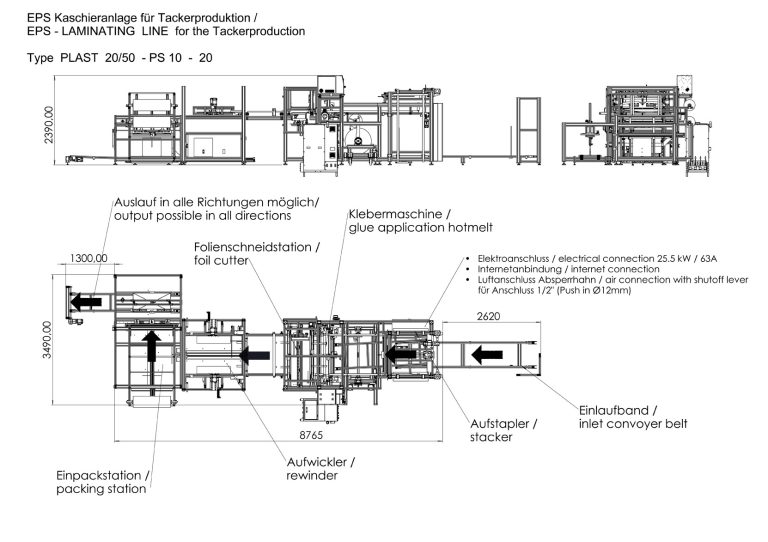

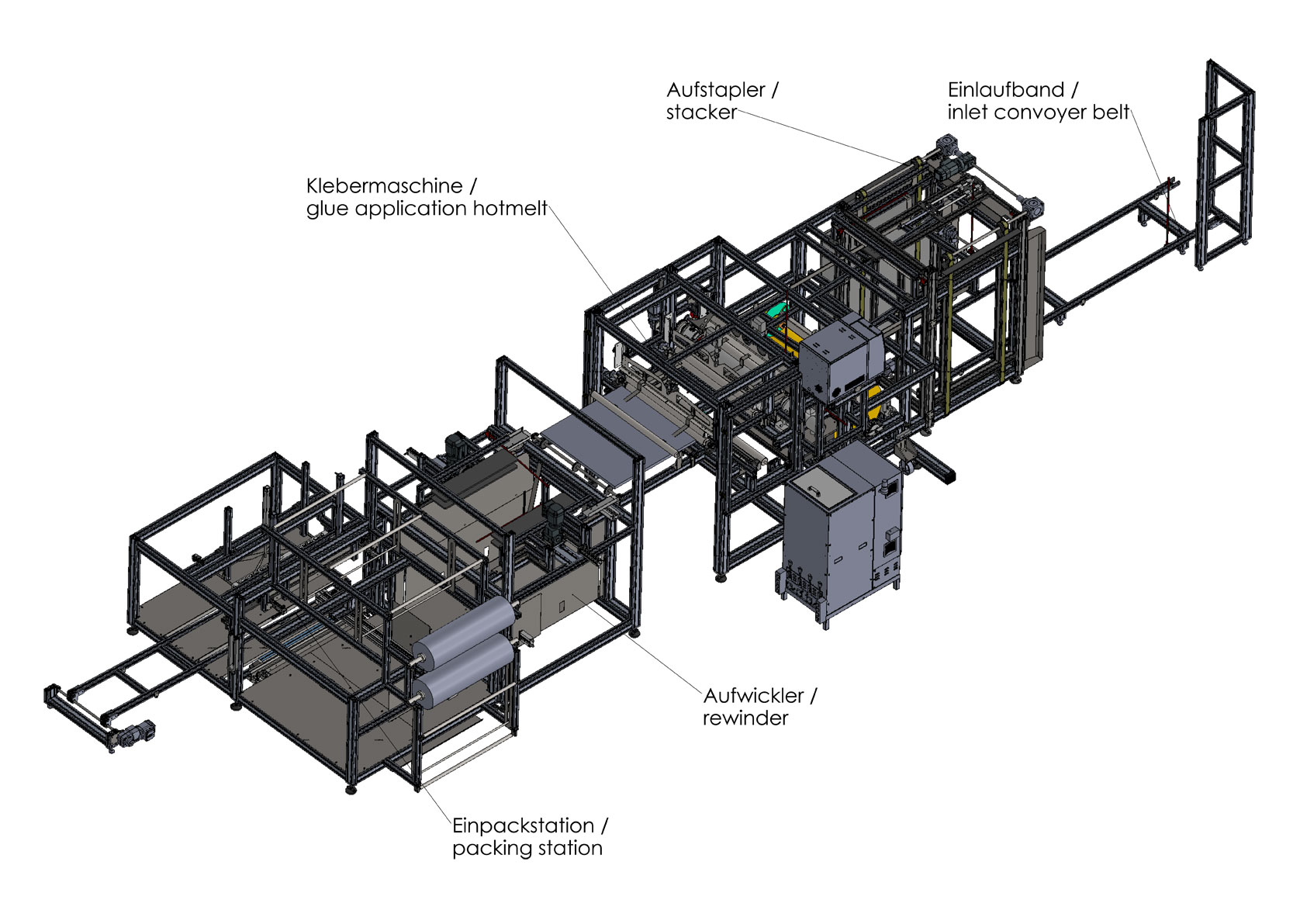

EPS insulation boards in thicknesses from 20 mm to 50 mm in 1000 x 1000 mm format are laminated with fibre-reinforced PP films of approx. 100 g/m2. The HOT-Melt adhesive quantity setting can be varied on the adhesive application machine and can be infinitely adjusted from as little as 30 g/m2 to 60 – 70 g/m2 if the film is well bonded to the panel material.

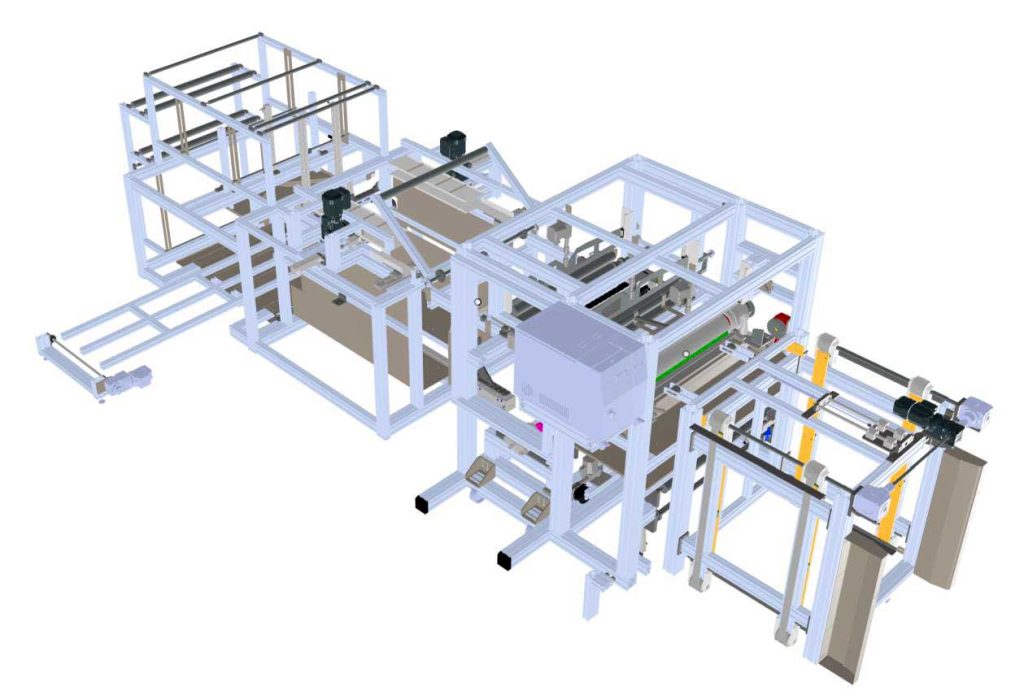

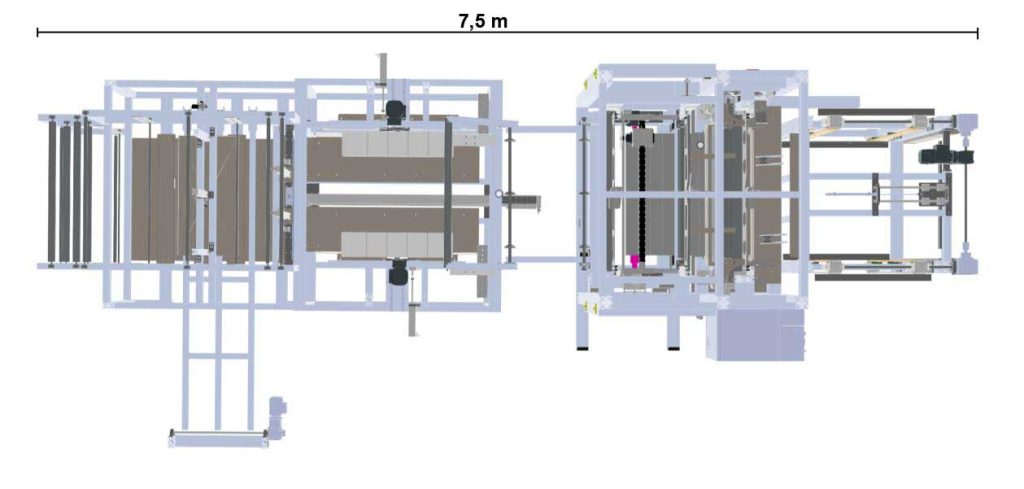

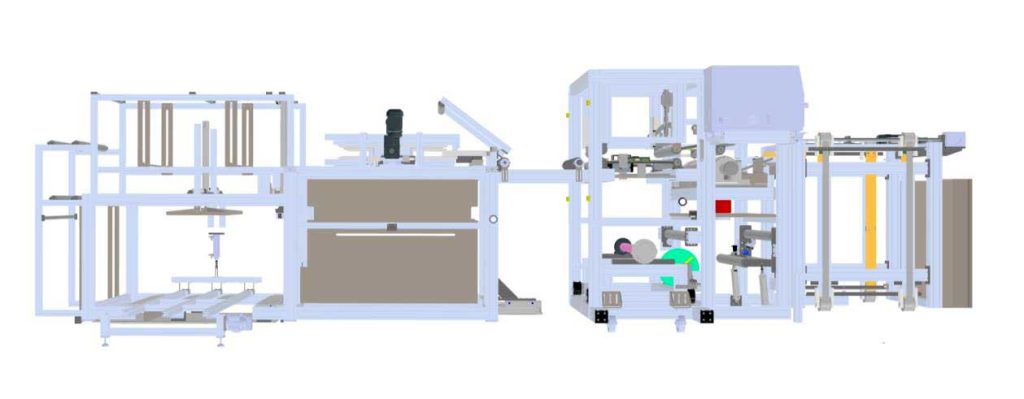

The film-laminated sheet material can be produced with the laminating system as single sheets 1 m2, folded sheets or sandwich sheets 2 m2 or as rolls of 10 m2. The production output – regardless of production – is approx. 800 m2 /h or 6,000 m2 /shift.

We have a major advantage over the competition in that we can produce any panel product with a film overhang to prevent cold bridges and can also equip the film overhang with or without double-sided adhesive tape for any panel format.

Finally, it should be noted that completely flat rolls can be produced and a packaging station can also be supplied as an option for both rolls and sheet material. When the production machine is fully equipped with packaging and sheet feeding, the systems are in fully automatic operation with SIMATIC S7 control without the need for personnel.

EPS laminating line with HOTMELT adhesive application for TACKER board production of EPS systems for floor heating

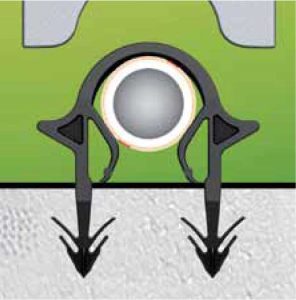

Tacker for quick positioning of hoses on EPS panels with clip clamping elements for heating pipes from 6 – 20 mm

from 6 – 20 mm

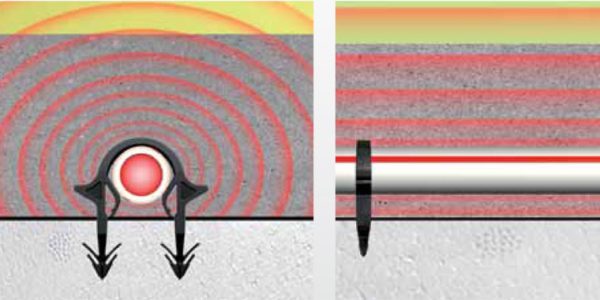

Vapour barrier: The PE grid foil bonded to the EPS panels with hotmelt adhesive prevents moisture absorption and guarantees a good and quick hold of the heating hoses with the Klips-Tacker system.

Thermal insulation without thermal bridges:: The roller tracks with overlapping grid film are attached to the next roller track with self-adhesive strips and form a fixed unit without thermal bridges.

Economical: No other system– whether dimpled or hook and loop – can be installed so easily, securely against hose displacement, quickly and without problems, with minimum waste and lowest costs.

Laying distance: The PE carrier foil equipped with a grid enables any type of laying and hose spacing.

Example:

Material: PST-SET

step-sound insulation

improvement: 29 DB

Nominal thickness: 20 / 50 mm

Vapor barrier: PE grid foil 0.2 mm

Thermal transmittance

resistanceat 32/30 = 0.66 m2 K/W

Fire class: E

Grid dimension: 5 / 10 cm

Packaging unit: 10m2 roll, 2m2 sandwich, 1m2

Singleformat: 10 x1 m = 10m2, 2×1 m = 2m2,

1×1 m = 1m2

Maschinen- und Anlagenbau

A-9220 Velden(Austria)

Klagenfurter Straße 45c

Telefon Tel.: 0043 680 333 2818

E-Mail: tischler@timatec.at